Quick Details

Application: steel reinforced pipe

Plastic Processed: HDPE, steel strip

Screw Design: Single-screw

Automatic Grade: Automatic

Place of Origin: Jiangsu China (Mainland)

Brand Name: Sansu_PE steel reinforced pipe extrusion line

Voltage: 415V/50HZ, 440V/60HZ, 220V/60HZ, 380V/50Hz,

Power(W): 120KW

Dimension(L*W*H): 29M*2.5M*3.5M

Weight: 8-25T

Certification: CE/ISO/BV

After-sales Service Provided: Engineers available to service machinery overseas

Lifetime: More than 8 years

Guarantee time: 12months after machine installation in customer’s factory

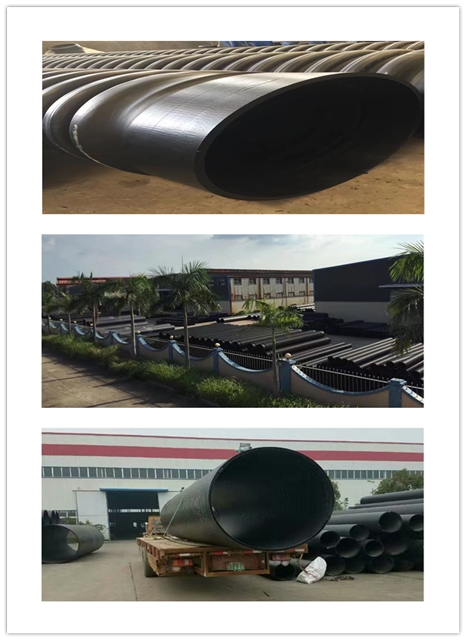

Pipe range: 300-3000mm

Stiffness steel: SN4, SN8,SN12.5

Inverter: ABB

Temperature controller: RKC

Low voltage unit: DELEX

Contactor: Siemens

Usage of steel reinforced pipe:

* Municipal Engineering: used for building rainwater pipes, underground drainage, sewage, ventilation tubes.

* Communication pipe: rail, road communication, communication cable, fiber optic cable protection tubes.

Industry: Widely used in industrial fields sewage pipes.

* Agricultural Engineering: used for farmland, orchards, tea plantations and forest irrigation.

* Road works: as railway, highway infiltration, drainage.

* Mine: for mine ventilation, air supply, drainage, mud tubes.

* Sports venue: as golf courses, soccer and other sports venues seepage drains.

* Port, dock project: large airport, port, pier drainage, sewage and so on.

* Landfill sewage collection pipe. Sewage treatment system

* Water storage system. Slow flow for interception storage system.

* Seawater pipelines.

Pipe Advantages:

* ring stiffness much more high than the common HDPE winding pipe..

* uniform wall and property of pipe, there is no weak link.

*

no leakage. Between the strip and the strip are welded together with

the same material (HDPE excellent sealable), and rolling welded with

uniform welding line

*

corrosion resistance, long life. Galvanized steel strip welded in HDPE

profile completely, the strip will not corrode, pipeline life expectancy

of 50 years.

*

big length of pipe. In the pipe production, both HDPE profile and steel

strip all can welded to continue, * small thickness of pipe, low cost

of pipe. Elasticity Modulus of the steel is 200 times of HDPE, and the

price of HDPE is three times the steel, therefore, high strength steel

support the HDPE covering, so the wall of pipe is thin. For example SN8, Φ800 diameter, the common HDPE winding pipe wall thickness up to 50mm; while the PE-steel wall thickness of pipes is only 22mm.

*

diameter adjustable. The same strip can produce different diameter pipe

??according to the request of pipe stiffness. therefore, it is flexible

to arrange the production.

*

Easy installation of pipeline. Pipes and pipes, pipe and manhole have 3

type of connection, installation speed, low cost of installation.

* anti-shock and breakage.

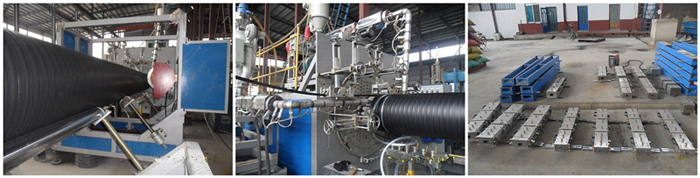

The Main specification of steel reinforced pipe extrusion line

|

pipe diameter |

300-1200mm |

800-2000mm |

1200-3000mm |

|

profile extruder model |

SJ75 |

SJ75 |

SJ90 |

|

extruder motor |

37KW |

55KW |

75KW |

|

extruder heating power |

18KW |

24KW |

36KW |

|

profile mould |

4 sets |

5 sets |

6 sets |

|

mould material |

3Cr17 |

||

|

vacuum table dimension |

6000(L)*1100(W) |

6000(L)*1100(W) |

6000(L)*1200(W) |

|

vacuum pump |

5.5KW*2 |

5.5KW*3 |

5.5KW*4 |

|

water pump |

3KW*1 |

3KW*1 |

3KW*1 |

|

dry blower |

750W |

750W |

750W |

|

effective haul off length |

1800mm |

2000mm |

2500mm |

|

haul of motor |

1.5KW*2 |

1.5KW*2 |

2.2KW*2 |

|

coiler |

15KN |

||

|

dimension of winding |

6*2.2*4.5m |

6.8*2.8*5m |

7.5*3.6*6.5m |

|

side extruder model |

SJ45 |

||

|

extruder motor |

15KW |

||

|

extruder heating power |

12KW |

||

|

top extruder model |

SJ75 |

SJ75 |

SJ90 |

|

extruder motor |

37KW |

45KW |

75KW |

|

extruder heating power |

22KW |

28KW |

42KW |

|

winding motor |

15KW |

22KW |

30KW |

|

roller size |

66*1000mm |

90*1200mm |

110*1400mm |

|

length of pipe |

6-12m |

||

|

cutting disk |

Alloy disk |

||

|

cutting precision |

<10mm |

||

|

steel rolling machine |

4 sets |

5 sets |

6 sets |

|

steel strip |

cold rolling galvanized steel strip |

||

|

rolling motor |

5.5KW |

7.5KW |

22KW |