Condition: New

Application:Pipe

Plastic Processed:PVC

Screw Design:Double-screw

Automatic Grade:Fully Automatic

Place of Origin:Jiangsu, China (Mainland)

Brand Name:SANSU

Model Number:SANSU-PVC pipe

Voltage:Customized

Power(W):11-110KW

Dimension(L*W*H):20m*2m*1.8m

Weight:8-20T

Certification: BV CE SGS

After-sales Service Provided: Engineers available to service machinery overseas

machine:Manufacture PVC UPVC pipe extruder making machine with price

pipe diameter:16mm-800mm

Raw material:UPVC PVC Resin

Inverter:ABB Frequency Controller

motor: SIMO

Warranty: 24 months

extruder type: high efficient double screw

finish product:PVC UPVC pipe

temprature control:Japan RKC

contactor:SIEMENS

Product Description

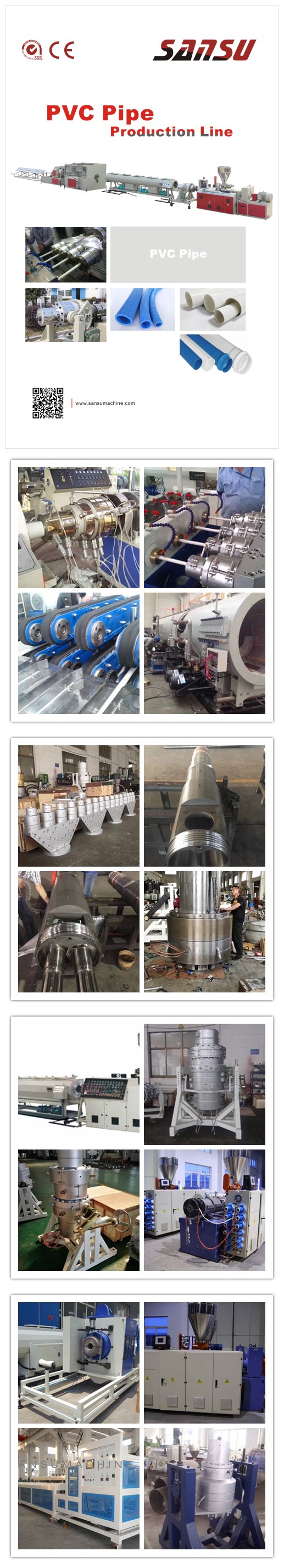

This PVC pipe production line is widely used for producing PVC water supply pipe, drainage pipe and high voltage cable protection pipe. With CPVC pipe mold, it could also produce CPVC pipe. It is consist of SJSZ series extruder, mold, vacuum tank,spraying cooling tank, haul-off,cutting machine, stacker, and can produce PVC pipe from mixed powder directly.

The production line uses special designed screw and mould, which makes it easy forming, even plasticization, high capacity stable running and easy operation

|

Technical specifications for PVC Flexible Pipe Making Machines |

||||

|

Model |

Pipe Spec(mm) |

Conical twin screw extruder |

Max output(kg/h) |

Total power(kw) |

|

SSG63-PVC |

Φ20-Φ63 |

GSZ65/132 |

180-300 |

104 |

|

SSG160-PVC |

Φ63-Φ160 |

GSZ65/132 |

180-300 |

105 |

|

SSG250-PVC |

Φ75-Φ250 |

GSZ80/156 |

300-450 |

110 |

|

SSG315-PVC |

Φ250-Φ315 |

GSZ80/156 |

300-450 |

216 |

|

SSG450-PVC |

Φ200-Φ450 |

GSZ92/188 |

650-750 |

290 |

|

SSG630-PVC |

Φ315-Φ630 |

GSZ92/188 |

750-850 |

350 |

|

SSG800-PVC |

Φ500-Φ800 |

GSZ135/31 |

950-1100 |

410 |

Process flow:

PVC powder + additive → mixing

Spring feeder → twin screw extruder → mould → vacuum calibration machine → haul off machine → cutting machine → stacker

What can we bring you?

1.High-quality equipment and highly competitive market prices can bring you more profits.

2. More than 15 years of plastic extrusion machine industry experience, can solve the various problems in the work. Improve machine efficiency for you.

3. More than 15 years of plastic extrusion machine industry experience, has a good supply system, can provide you one-stop service with the pre-sale , sale and after sale service. Save your purchasing cost and maintenance costs

1. The Small Additives Auto Weighing System

We developed this auto weighing system especially for PVC pipe and profile production to instead of manual weighing. It could auto weigh the additives in PVC pipe and profile formula besides the PVC and CACO3. The operator could only manually weigh PVC and CACO3, for other powder additives, this auto weighing system could weigh the quantity for one batch use automatically. This system could avoid the mistake of manual weighing and also keep the workshop clean.

This system could auto weighing 6-9 kinds of powder or granules additives. If you have more than three extrusion line, then this automatic additives auto-mixing system will be your good choice for saving labor.